品牌:NTH

车削加工抗震烈度制作 小腿伸出制作 无拉簧无磨损情况

MECHANISM FOR OPENING THE ARMS OF THE STEADY REST WITHOUT SPR💛INGS AND FREE FROM WEAR.AND ANTI-VIBRATION DESIGN FOR MACHINING.

润滑 选配 OPTION OF LUBRICATION

手动润滑:低润滑,用于中等工作条件,小切削量

集中润滑:由于恶劣工作条件下,大切量

油气润滑:用于大切削量,粉尘或强力冷却的最恶劣条件下

Manual lubrication: Low cost solution for medium working conditions and low swarf.

Central lubrication: For heavy working conditions and high build up of swarf

Central lubrication oil and air: For heaviest cutting conditions with high built up of swarf,dust or coolant

滚轮 选配 OPTION OF LUBRICATION

NTH-OMSR滚轮(精度等级P05)是专为中心架设计

特殊的密封保证了最高的精度和使用寿命

标准配置:圆柱型滚子1套

选配:腰鼓型滚子用于跟刀式应用的中心架

Omatei rollers (precision class P05) specially developed for our Steady Rests

Special sealing ensures highest precision and service life

Standard equipment: 1 set of cylindrical rollers

Option: Spherical rollers (for 🎶travelling Steady Rest🥂s)

|

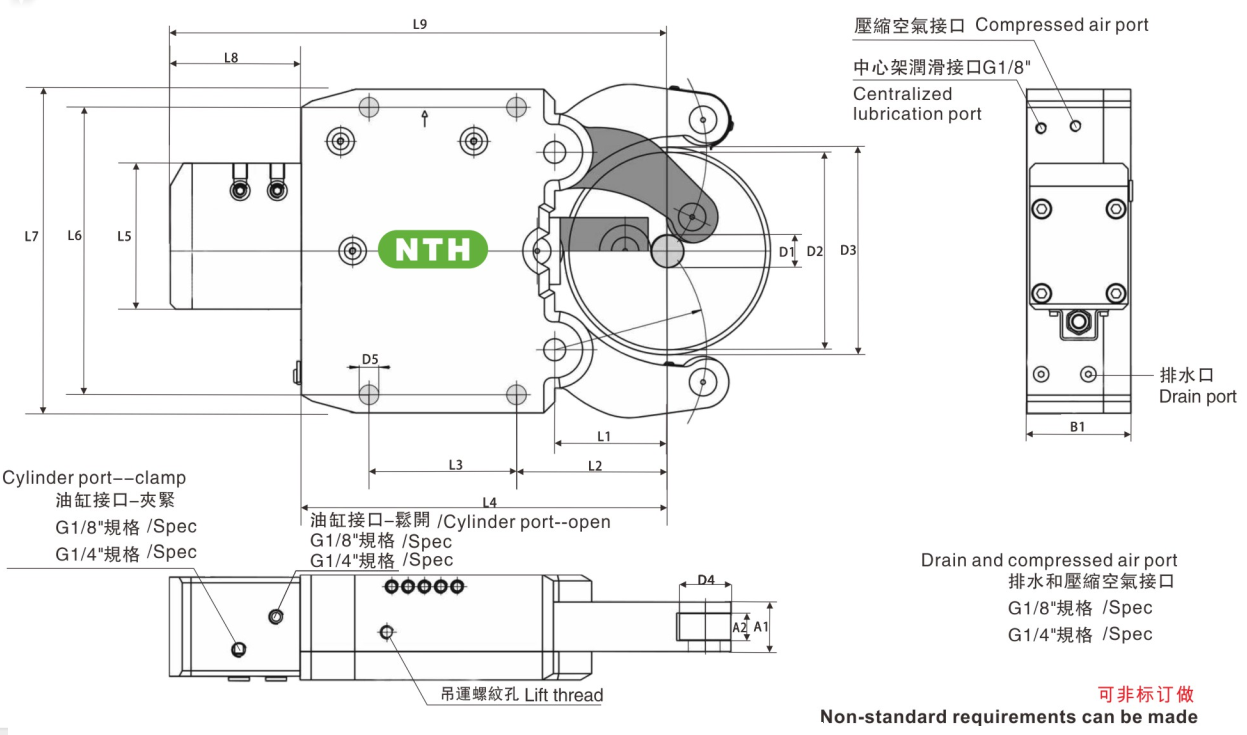

NTH-OMSR 型号/Model 规格/Spec |

OMSR-A1 | OMSR-A2 | OMSR-A3 | OMSR-A4 | OMSR-A5 | OMSR-A6 | OMSR-A7 | OMSR-A8 |

|---|---|---|---|---|---|---|---|---|

| D1 (mm) | 6 | 8 | 12 | 20 | 50 | 30 | 50 | 85 |

| D2 (mm) | 70 | 101 | 152 | 162 | 200 | 245 | 310 | 350 |

| D3 (mm) | 76 | 105 | 162 | 170 | 202 | 252 | 318 | 352 |

| D4 (mm) | 24 | 35 | 47 | 47 | 47 | 52 | 62 | 62 |

| D5 (mm) | 11 | 14 | 18 | 18 | 18 | 18 | 24 | 24 |

| L1 (mm) | 37 | 51 | 85 | 93 | 103 | 128 | 160 | 180 |

| L2 (mm) | 52 | 70 | 115 | 123 | 138 | 146 | 178 | 198 |

| L3 (mm) | 66 | 85 | 135 | 135 | 135 | 240 | 270 | 270 |

| L4 (mm) | 149 | 195 | 312 | 320 | 335 | 448 | 510 | 530 |

| L5 (mm) | 82 | 103 | 138 | 138 | 138 | 152 | 160 | 160 |

| L6 (mm) | 140 | 170 | 262 | 262 | 262 | 262 | 400 | 400 |

| L7 (mm) | 160 | 195 | 295 | 295 | 295 | 295 | 440 | 440 |

| L8 (mm) | 65.5 | 82 | 116 | 116 | 120 | 155 | 187 | 187 |

| L9 (mm) | 214.5 | 277 | 428 | 436 | 455 | 603 | 697 | 717 |

| A1 (mm) | 28 | 35 | 45 | 45 | 45 | 60 | 75 | 75 |

| A2 (mm) | 15 | 19 | 25 | 25 | 25 | 25 | 29 | 29 |

| B1 (mm) | 63 | 75 | 95 | 95 | 95 | 110 | 145 | 145 |

|

工作压力最小/最大 Work pressure Min./Max. (bar) |

6/70 | 8/70 | 8/80 | 8/80 | 8/80 | 8/80 | 8/80 | 8/80 |

|

最大夹紧力/滚轴 Max clamping force of the roller (daN) |

165 | 450 | 1000 | 1000 | 1000 | 1000 | 2000 | 2000 |

|

整个夹持范围的定位精度 Position accuracy within the clamping range (mm) |

0.02 | 0.02 | 0.04 | 0.04 | 0.04 | 0.04 | 0.06 | 0.06 |

|

重复定位精度 Repeatability accuracy (mm) |

0.005 | 0.005 | 0.007 | 0.007 | 0.007 | 0.007 | 0.01 | 0.01 |

|

滚轮最大线速度 Max line speed of the roller (m/min) |

800 | 800 | 725 | 725 | 725 | 715 | 700 | 700 |

| 重量 Weight(KG) | 7.8 | 13.9 | 57 | 57 | 58.8 | 116.5 | 173.8 | 177.8 |